Reibung, Adhäsion & Rissausbreitung

Reibung in Gummi

The main contribution to rubber friction when a rubber block slides on a rough substrate, i.e., a tire on a road surface, is the viscoelastic energy dissipation in the surface region of the rubber. These result from the pulsating forces acting on the rubber surface from the substrate asperities. Recently we developed a theory that describes this dissipation process accurately, and also predicts the velocity dependence (and the time-history dependence) of the rubber friction coefficient. The results depend only on the (complex) viscoelastic modulus of the rubber and the substrate surface roughness power spectra, and agrees well with experiment.

Mikrostruktur der Füsse von Insekten und Eidechsen

How can a fly or a cricket walk on a glass window, or a lizard move on a stone or concrete wall? These fundamental questions have interested scientists for many years, and recently very important work has been performed in order to gain a deeper insight into these questions. The adhesive microstructures of insects and lizards is the results of perhaps millions of year of development driven by the principle of natural selection. Hence one may expect the adhesive structures to be highly optimized and it is clear that a good understanding of the construction and function of the adhesive structures may lead to new improved man-made adhesives. At IFF we study adhesion relevant to biological systems, e.g., flies, crickets and lizards, where the adhesive microstructures consist of either smooth attachment pads, as shown in the figure for a cricket adhering to a smooth vertical window glass, or arrays of thin fibers.

On the mechanism of adhesion in biological systems (PDF, 185 kB)

Rissausbreitung

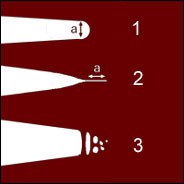

The singular stress region at a crack tip in continuum mechanics can be removed by (1) tip blunting (tip diameter a), or (2) by introducing a lateral region (linear size a) over which bond breaking occurs. The latter is the so called Barenblatt process zone. The crack tip process zone in most materials is very complex, involving cavity formation, stringing, chain pull-out (for polymers), and bond breaking (3).

Our treatment of crack propagation in viscoelastic solids can be extended to include the crack tip flash temperature, which - because of the low heat conductivity of rubber materials - is likely to be of extreme importance already at relative low crack tip velocities.